Services

At Spartek, Inc., we offer a diverse range of advanced manufacturing capabilities to meet the needs of various industries. Our injection molding department excels from large-tonnage production to precision molding, ensuring consistency and accuracy. In our inline metallization department, we handle high-volume runs with efficiency, while our vacuum metallizing department delivers both stunning, durable small-batch specialty products and high-performance, large-scale production. With cutting-edge technology and a focus on quality, we provide solutions that meet the highest standards of durability and aesthetics.

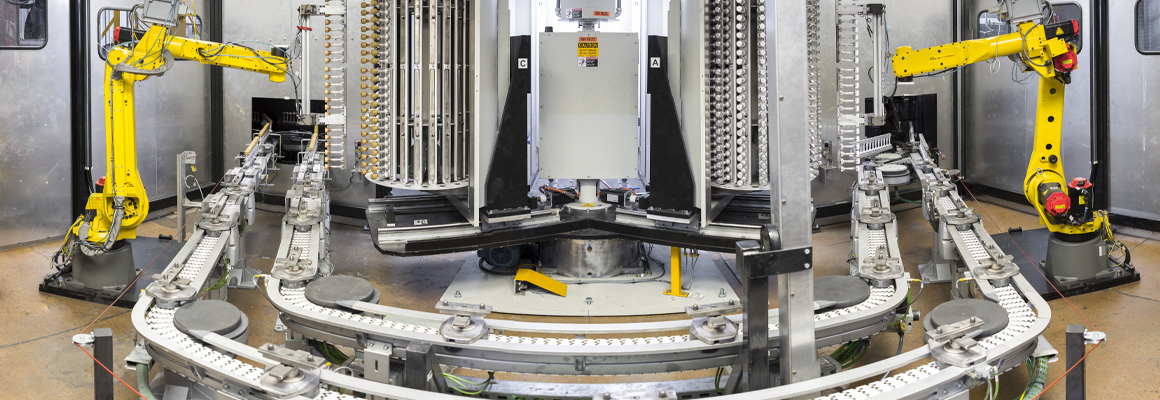

Inline Metallizing

Our advanced Inline Vacuum Metallizers and Coating Lines with PVD sputtering technology, produce high-quality parts efficiently and cost-effectively, with no manual handling.

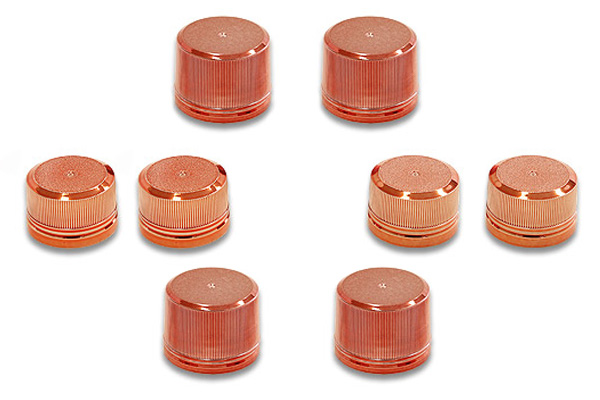

Vacuum Plating & Metallizing

Our vacuum plating and metallizing enhances durability and appearance with advanced metal coatings. Our facilities handle both small and large orders with precision, ensuring top-quality finishes every time.

Injection Molding

Our high-quality injection molding, produces precise components with advanced technology. Our range of presses and automation ensures efficient production for various industries, including consumer products and packaging.