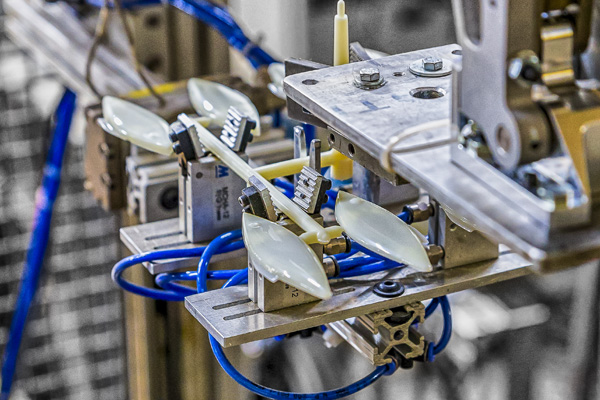

Injection Molding

With our comprehensive design and manufacturing capabilities, Spartek, Inc. is a major provider of close tolerance, highly detailed, and complex injection molded parts. Leveraging the very latest injection molding methods and technologies, we can supply small- to medium-sized parts that exhibit an exceptional level of quality.

Spartek’s engineers work with you to create intelligent designs that address all functional and structural aspects of your component. Our multi-component and insert molding enable Spartek to provide complex parts with precise geometries and precision surfaces. This precision reduces the need for downstream finishing and assembly.

Spartek is home to eleven injection molding presses ranging from 28-ton to 1,500-ton. The range of press sizes allows us to manufacture small precision components weighing just a few ounces as well as large structural components weighing up to 15 lbs. Our robotics and other automation technologies enable us to both expedite and exert repeatable control over the injection molding process.

At Spartek, we work with many types of commodity-type and engineering plastics. We have the flexibility to fulfill low and high-volume orders in a timely manner to meet the strictest production deadlines.

Spartek, Inc. manufactures high-quality parts for use in:

- Construction

- POP Displays

- LED Lighting

- Agriculture

- And more

Contact us directly to learn more about our injection molding capabilities or to request a quote.