Inline Metallizing

At Spartek, Inc., our 50+ year history in the field of vacuum metallizing has allowed us to grow into a trusted industry leader. Our success as a manufacturer is based on a culture of quality and a continual investment in developing the newest technologies and manufacturing processes.

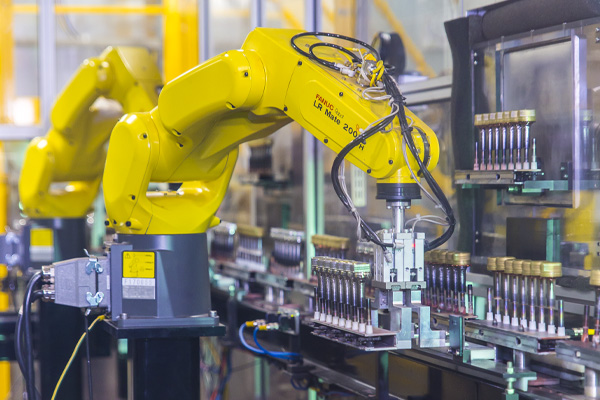

Spartek, Inc. is home to three advanced Inline Vacuum Metallizing and Coating Lines, powered by industry-leading PVD sputtering technology. These state-of-the-art systems represent the forefront of inline metallization, with the capability to produce millions of parts annually, all without any manual handling from start to finish. Our lines can accommodate a wide range of sizes and geometries, providing flexibility while maintaining the highest quality standards.

Engineered for maximum efficiency, our Inline Metallizing and Coating Lines deliver the lowest part cost in the industry with continuous quality monitoring built into the process. By eliminating manual handling and utilizing advanced process technology, we minimize scrap rates and virtually eliminate the risk of part loss, which is common in traditional metallizing systems.

With automation at every stage, we ensure 100% quality control without additional labor costs or delays, offering superior cost reductions. We have the capacity and expertise to meet your needs.

For more information about our Inline Metallization and Coating Lines, contact us directly.